Rust has been the cancer of iron and steel since the dawn of the Iron Age. For the farmer, rust is responsible for a great financial loss over time. Wet environments, corrosive chemicals and fertilizers, and non-neutral soils all conspire to destroy buildings and equipment. Zinc galvanize and ordinary paint can delay rust, but after a short time, they wear or flake away and the problem returns.

Ordinary paints require rust to be sanded, sand blasted, acid etched, or otherwise mechanically removed before they can be applied. This process is very labor intensive and prone to error.

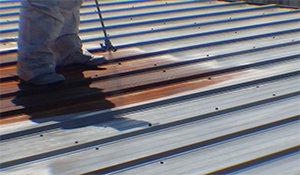

Professional Application Large Roof Project

Project Description

A 48,000 sf galvanized metal roof, badly in need of repair or replacement due to Stage 3 and 4 Corrosion was coated with Rust Bullet Standard Formula Powers Incorporated completed the job using a three man crew and applying 12 mil dft in a two coat application the entire project was completed, including prep and cleanup in five days. Choosing a Rust Bullet repair over replacement provided an initial savings to the customer of over $300,000.The future benefits of a long lasting protective coating will be a continued savings on repair and replacement for many years to come.

Project Description

The barn is a metal clad wood composite with galvanized and painted surfaces. The bottom of the walls on the interior of the stalls are deep bedded and frequently in contact with damp straw and manure for much of the winter. As a result, the paint is oxidized in places and there was a lot of rust and scale on the galvanized metal framing around the panels. The barn is about 8-9 years old, now, and houses horses and dairy goats.

We began the surface prep by pressure washing the walls and removing the rubber mats on the floors. We used a disc sander to remove as much of the rust as possible from the metal surface areas as well as to lightly scarify the painted surfaces and oxidized areas of the walls.