CONCRETE FLOOR PROTECTION

Project Information:

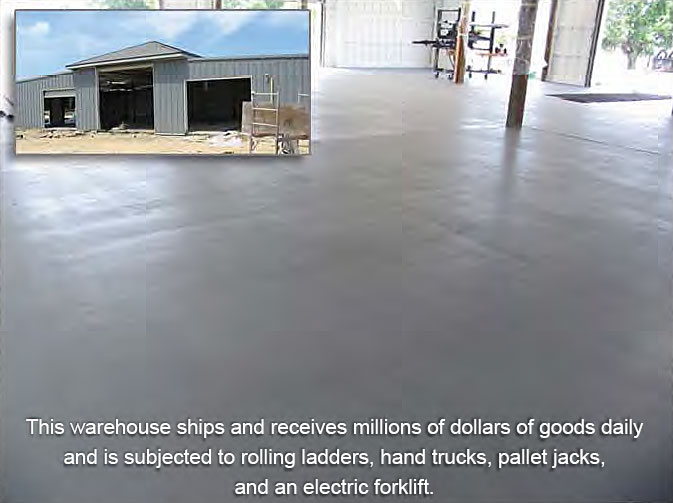

Project Name: Concrete Floor Protection

Contractor and Applicator: Warehouse Owner

Application: Brush & Roller

USA

2010

Project Description:

Concrete is the world’s most commonly used building material. Pliable and flexible when newly mixed and strong and durable when hardened explains why this remarkable material can build skyscrapers, bridges, sidewalks, superhighways, houses, dams, sewer pipes and floors. Concrete has been a reliable and versatile product for centuries. Chosen for its strength and durability, concrete is expected to withstand the most abusive conditions. It is subjected to the destructive effects from harsh chemical spills, abrasive objects, moisture, and the impact from heavy tools and machinery often resulting in an unsightly appearance and damage requiring costly repairs or replacement. Rust Bullet, with its Patented New Technology for rust and corrosion control, also provides outstanding protection to many other surfaces, including concrete.

Rust Bullet protective coating will:

- provide excellent chemical resistance

- provide protection from abrasives

- seal a surface from moisture

- allow easy clean up of spills

- prevent concrete from sweating

- reduce dust

- fill cracks, gaps and chips

- enhance appearance

- add years of life to concrete surfaces

Rust Bullet not only improves the appearance of concrete, it provides an impervious shield allowing easy clean up of oil, grease and chemical spills along with strong protection against impact and abrasives.

Application is quick and easy as well. Power wash or thoroughly rinse off dirt and debris and let the surface dry completely. Rust Bullet is self leveling and can fill crack, gaps and chips up to ¼”. For a slip resistant surface, sprinkle silica over a tacky coat of Rust Bullet, allow enough time for the sand to adhere, then apply the final coat of Rust Bullet.