Description

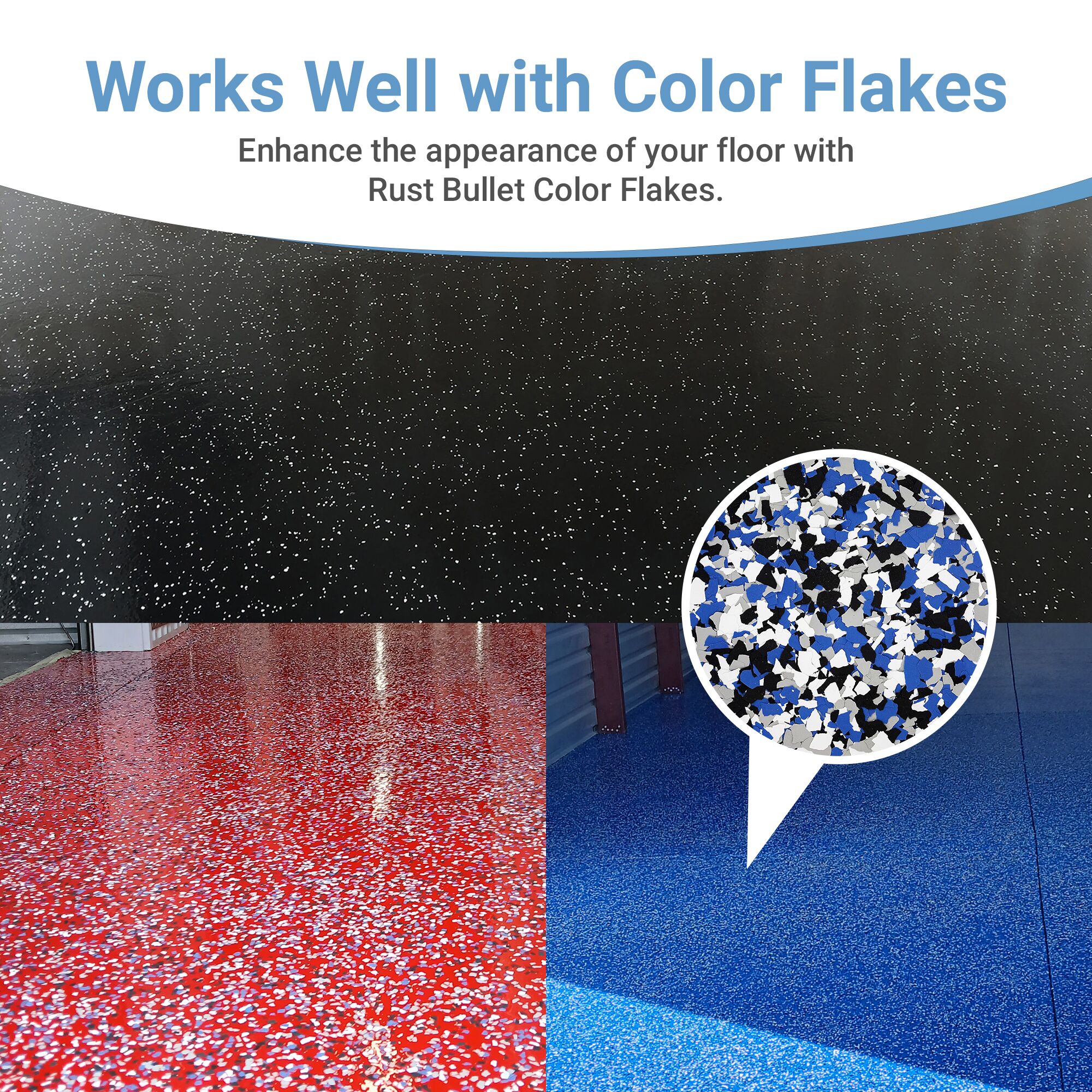

Available in a Quart, Gallon, or 5 Gallon Pail – Rust Bullet DuraGrade Concrete is a high-performance, durable coating specifically designed for concrete surfaces. DuraGrade Concrete provides exceptional protection against water, chemicals, UV rays, and abrasive conditions, making it ideal for both indoor and outdoor surfaces. Unlike traditional epoxy concrete coatings, Rust Bullet DuraGrade Concrete can be applied directly over concrete without the need for acid etching, grinding, or blasting. This saves time and labor costs. It is suitable for a wide range of applications including garages, warehouses, industrial floors, and even decorative concrete surfaces. Rust Bullet DuraGrade Concrete is an excellent choice for anyone seeking a reliable, easy-to-use, and long-lasting concrete coating solution. Whether for industrial, commercial, or residential use, it provides an efficient and cost-effective way to protect and enhance concrete surfaces.

- The Premier Garage Floor Paint and Concrete Paint

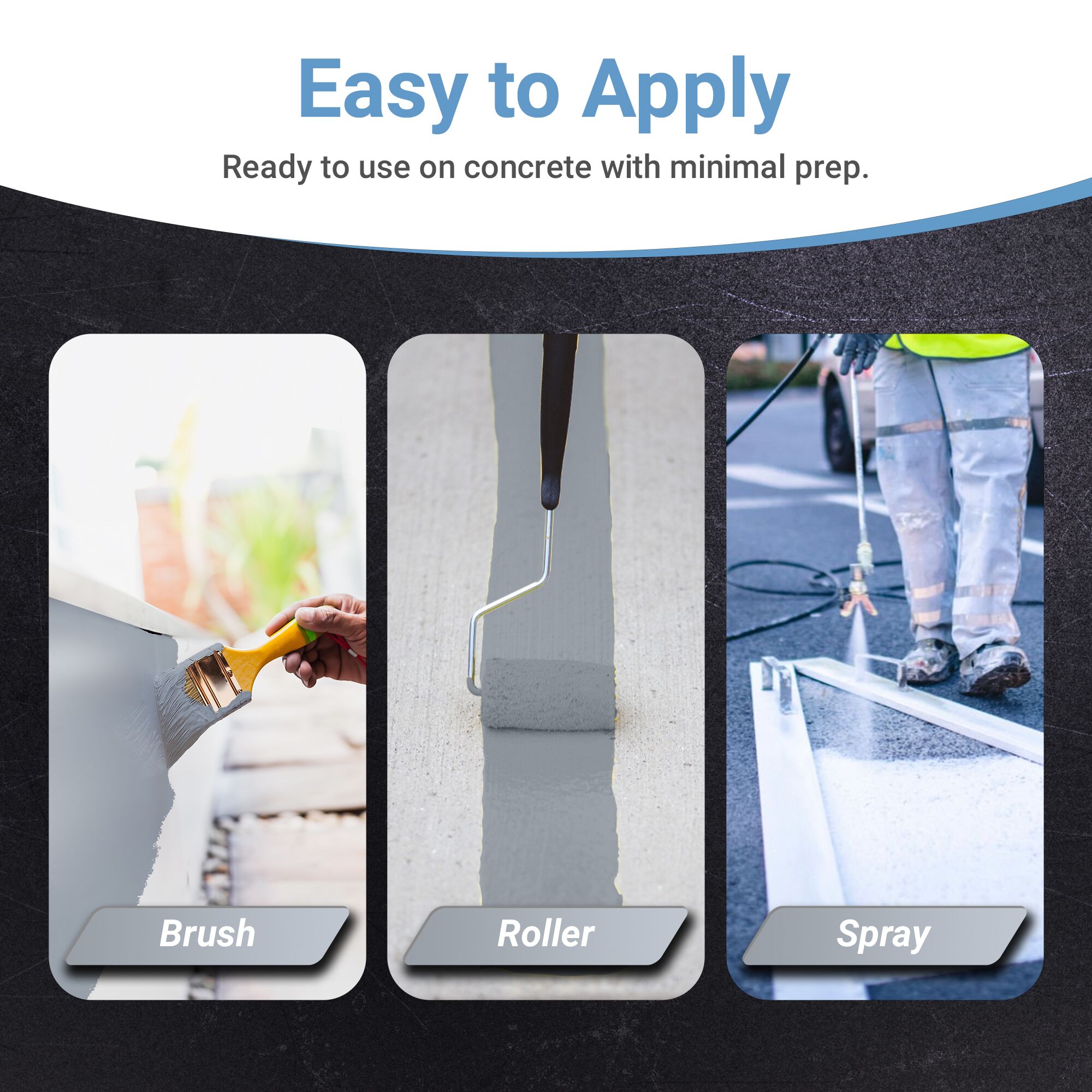

- Apply Directly to Concrete Without Acid Etching

- Scratch, Chip, Chemical and UV Resistant

- Excellent Resistance to the Peeling or Lifting Caused From Hot Tire Pick Up

- Requires No Primer, Base coat, or Topcoat

- Ideal for Indoor or Outdoor Surfaces

- Covers approximately 350 square feet, per gallon, per coat, depending on the porosity and texture of the substrate. A minimum two coat application is required

Color Disclaimer: The colors shown may not be exact due to screen image limitations. For absolute color fidelity, colors should be selected from physical samples, available upon request.