Cost of Corrosion – Railroad Cars

In 1998, 1.3 million freight cars and 1,962 passenger cars were operating in the United States. Covered hoppers (28 percent) and tanker cars (18 percent) make up the largest proportion of the freight car fleet. The type of commodities transported range from coal (largest volume) to chemicals, motor vehicles, farm products, food products, ores and minerals. Railroad cars suffer from both external and internal corrosion. The total annual direct cost of corrosion is estimated to be $0.5 billion, divided over external coatings ($0.25 billion) and internal coatings and linings ($0.25 billion).Railroad freight cars typically suffer from both external and internal corrosion. While external corrosion, primarily due to atmospheric exposure, is a concern, car appearance generally takes precedence. External corrosion is controlled by application of direct-to-metal coating systems (epoxies with or without urethane coating). Certain categories of cars, particularly tank cars, are leased by the shippers; therefore, the lessees often choose to apply an exterior paint to address the aesthetics. Internal corrosion is caused by corrosive cargo, such as coal, salt, or various acids.

In 1998, 1.3 million freight cars and 1,962 passenger cars were operating in the United States. Covered hoppers (28 percent) and tanker cars (18 percent) make up the largest proportion of the freight car fleet. The type of commodities transported range from coal (largest volume) to chemicals, motor vehicles, farm products, food products, ores and minerals. Railroad cars suffer from both external and internal corrosion. The total annual direct cost of corrosion is estimated to be $0.5 billion, divided over external coatings ($0.25 billion) and internal coatings and linings ($0.25 billion).Railroad freight cars typically suffer from both external and internal corrosion. While external corrosion, primarily due to atmospheric exposure, is a concern, car appearance generally takes precedence. External corrosion is controlled by application of direct-to-metal coating systems (epoxies with or without urethane coating). Certain categories of cars, particularly tank cars, are leased by the shippers; therefore, the lessees often choose to apply an exterior paint to address the aesthetics. Internal corrosion is caused by corrosive cargo, such as coal, salt, or various acids.

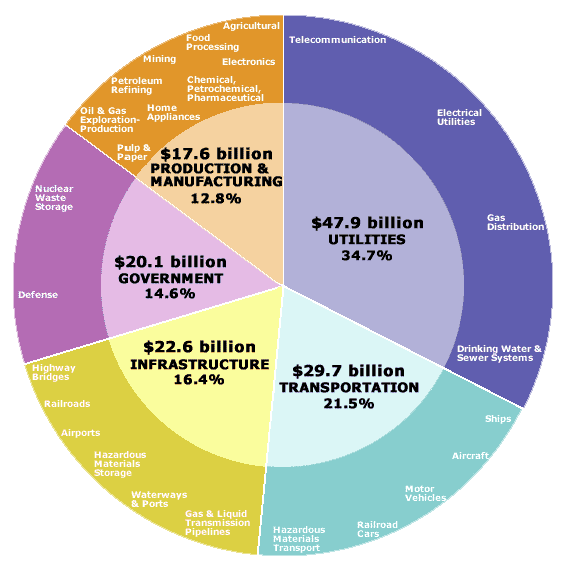

How Much is Corrosion Costing You?

-

facebook

-

YouTube

Outside of US: 1-775-829-5606

Toll Free: 1-800-245-1600

Canada Toll Free: 1-800-789-3993

Email: Support@RustBullet.com

Monday-Friday 8:30am to 5:00pm PST

300 Brinkby Ave., Suite 200

Reno, NV 89509

USA

© 2025 Rust Bullet, LLC. All Rights Reserved.