Cost of Corrosion – Mining

Corrosion in the mining industry is not considered a significant issue. Interviews with several mining engineers indicated that equipment wear and tear was the primary concern in maintaining the equipment operational. Although various forms of corrosion could be identified in mining machinery, corrosion is not considered to be a life-limiting factor for this equipment. Maintenance painting is, however, heavily relied upon to control corrosion, and it is estimated that an average of $93 million is spent annually for the coal mining industry, which is a very small portion of the overall cost in the production and manufacturing category.

In the few instances where corrosion is a concern, the mining industry relies heavily on past experience and the knowledge of equipment suppliers to quickly resolve any problems in order to maintain production. There is general consensus among mining engineers that the life limiting factors for mining equipment is wear and mechanical damage before corrosion becomes an issue.

In the few instances where corrosion is a concern, the mining industry relies heavily on past experience and the knowledge of equipment suppliers to quickly resolve any problems in order to maintain production. There is general consensus among mining engineers that the life limiting factors for mining equipment is wear and mechanical damage before corrosion becomes an issue.

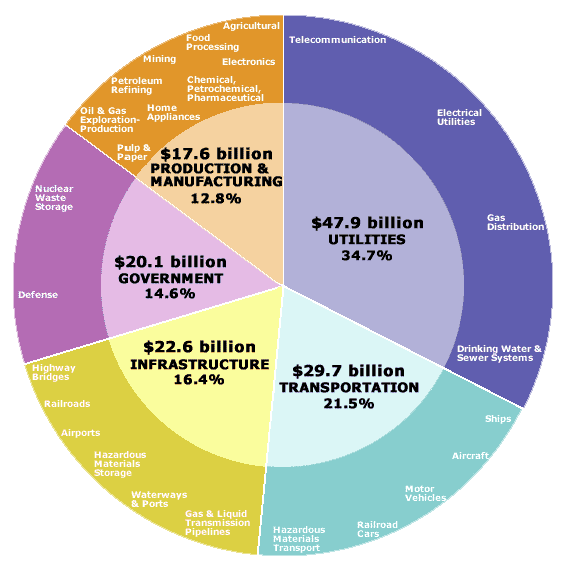

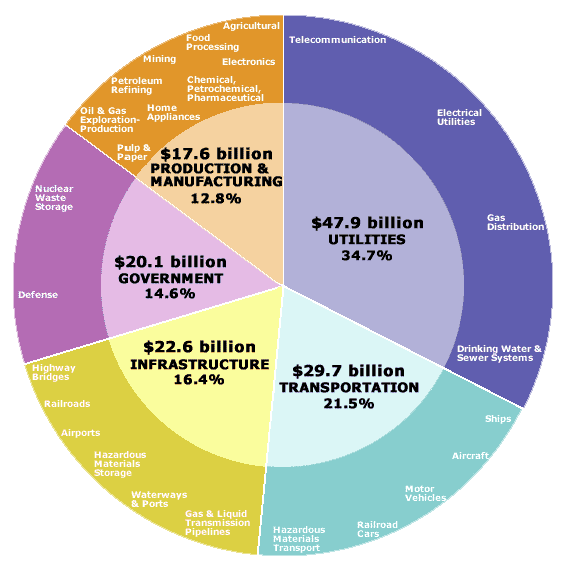

How Much is Corrosion Costing You?

-

facebook

-

YouTube

Outside of US: 1-775-829-5606

Toll Free: 1-800-245-1600

Canada Toll Free: 1-800-789-3993

Email: Support@RustBullet.com

Monday-Friday 8:30am to 5:00pm PST

300 Brinkby Ave., Suite 200

Reno, NV 89509

USA

© 2025 Rust Bullet, LLC. All Rights Reserved.