PROVIDING THE HIGHEST QUALITY RUST INHIBITORS AND CONCRETE COATINGS

SELECT AN

APPLICATION

WHAT ARE PEOPLE SAYING?

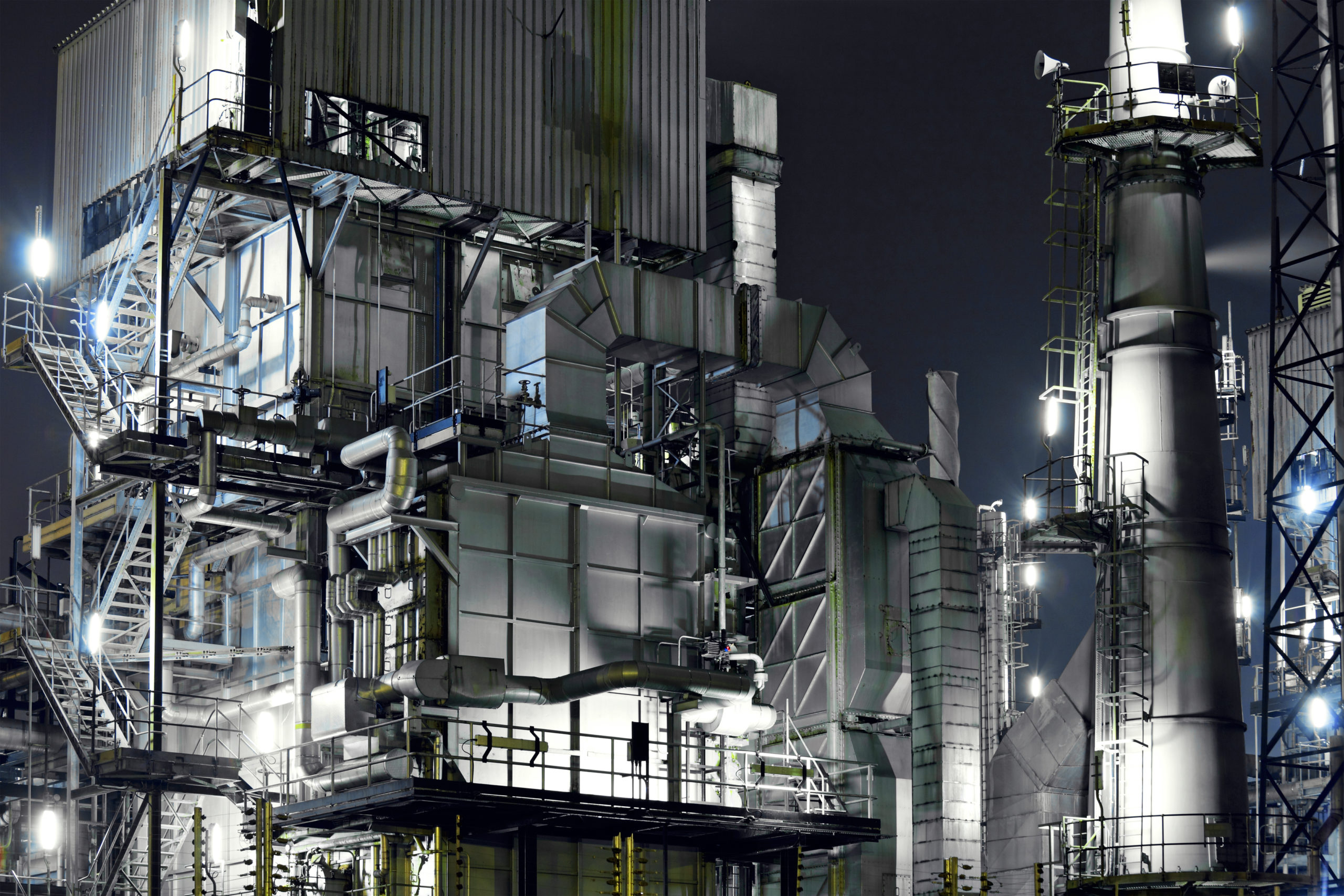

Jim B. – Industrial

I used this under my mower deck, I scraped it, wire brushed it and then used your metal blaster, washed it with hot water and let it dry. I then applied three coats of rust bullet letting it dry to the touch between coats. I will let you know how well it held up this fall when I clean everything up at the end of grass cutting season, Jim

Joe N. – Automotive

Wore mask and gloves – mixed for 3 min, used artist brush. Then painted direct on metal after dremel grinding away rust. Also painted some small spots with light surface rust. next day painted over with my touch-up paint. Extremely easy to use been a few months and still no sign of rust.

Phil M. – Clear Coat for Concrete

I own a performance car dealership and want to change the vibe of a used dealer. I did my entire warehouse showroom floor with this product. It came out excellent and it was an amazing product for the money. I bought the 5 gallon bucket and us 4/5 gallons on 2 coats of my 1500 sq ft warehouse. Concrete was relatively smooth though so keep that in mind.

CASE STUDIES

CASE STUDIES

All Garage Floors – A Long Lasting Garage Floor Paint

The quest to find a long lasting garage floor paint that will stand up to use and abuse may finally be over. That’s right, we said it. There really is a durable concrete floor paint available that will last for years, not peel, and not develop the dreaded hot tire lift problems associated with paint.

Maximum Drive – Rusty Parts Deserve a Bullet

It’s not often that we run a straight product test and example in Maximum Drive, but then it’s not often that we get ahold of a product like Rust Bullet. This product impressed us enough to warrant some special attention.

The High Performance Concrete Paint

Rust Bullet’s new flagship product DuraGrade Concrete is a high-performance, high-build, superior protective coating that can be applied directly onto concrete surfaces without acid etching. DuraGrade Concrete has outstanding adhesion to concrete surfaces and is scratch, chip, chemical, and UV resistant. This product requires no primer, basecoat, or topcoat and is easy to apply by brush, roller, or spray equipment. It protects from hot tire pickup and is perfect for indoor or outdoor surfaces. One of the best concrete and garage floor paints on the market today.

DISCOVER THE DIFFERENCE WITH